HyPlasma: cost-effective, clean hydrogen production units.

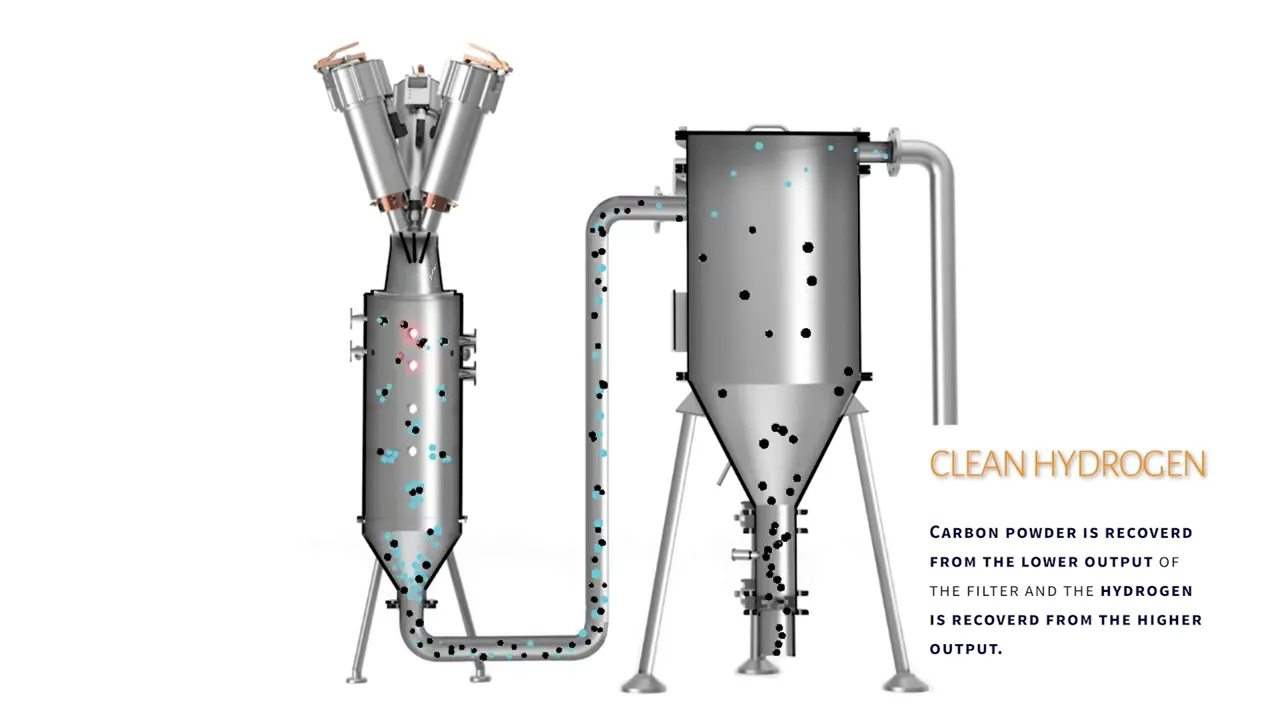

Our process uses our patented plasma technology to separate the methane molecule into hydrogen and solid carbon allowing a clean production of hydrogen at competitive costs.

Learn more below

Methane pyrolysis

We use the power of our plasma torches to “crack” the methane molecules (CH4) separating clean hydrogen (H2) from carbon powder (Cs).

Plasma

Using plasma, there are no emissions of CO2 in the atmosphere. Only solid carbon powder is generated as a by-product which is valorizable in the market.

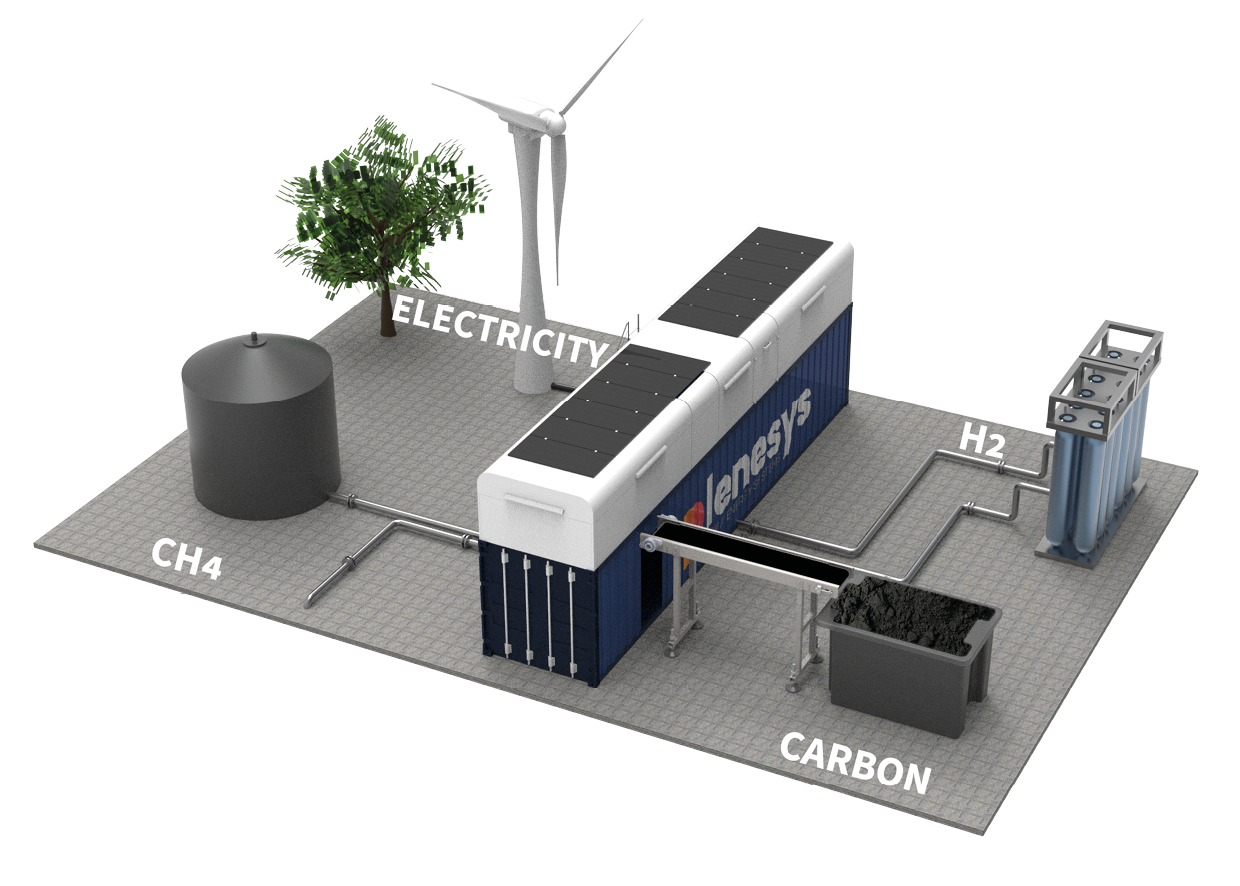

Decentralized and scalable

Our decentralized units are made with scalability in mind. The capacity of each unit can range from tens of tons to thousands of tons of hydrogen per year.

No CO2 emissions

While the most used H2 production process (namely Steam Methane Reforming) produces more than 10 kg of CO2 per kg of H2, the methane pyrolysis produces no CO2. Better, our process can be a sink to CO2 (from -10 to -22 kgCO2eq/kg H2) if biomethane and renewable electricity are used.

Competitive costs

HyPlasma consumes 5 times less electricity than water electrolysis, and while consuming (bio)-methane, the opex costs of producing a kg of H2 is more than 50% cheaper than electrolysis (not taking into account the valorization of the carbon powder by-product).

Flexible and scalable

Our units are highly scalable and flexible enabling them to be installed near to delivery points, meshing all the territory. Moreover, larger units can be installed for onsite production and use.

HyPlasma H2 production unit

0%

cheaper than electrolysis (w/o by-carbon powder valorization)

0kg

No direct CO2 emissions in the (bio)-methane pyrolysis

+0t/y

Units ranging from 50 to 1000 tons of H2 per year and more

WHY IS IT BETTER?

Learn below why.

Why is HyPlasma better?

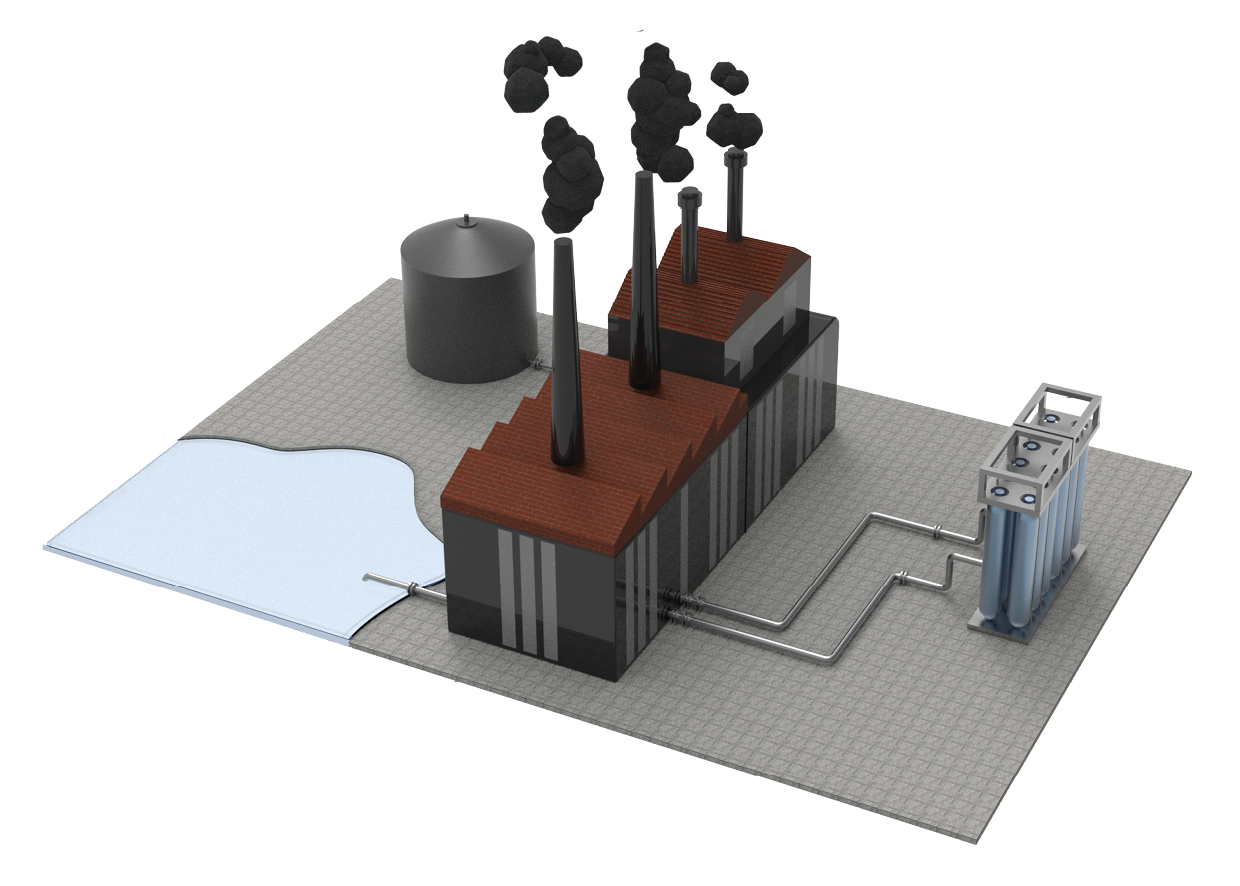

- The most dominant hydrogen production on the market today is Steam Methane Reforming (SMR). While hydrogen is thought to be a major player in the sustainable development and clean energy of tomorrow, SMR is a very polluting process. SMR uses natural gas (and water) as a feedstock, and more than 10 kg of CO2 are liberated in the atmosphere with each kg of H2 produced. Using this method is very discouraged if we want to produce climate friendly hydrogen.

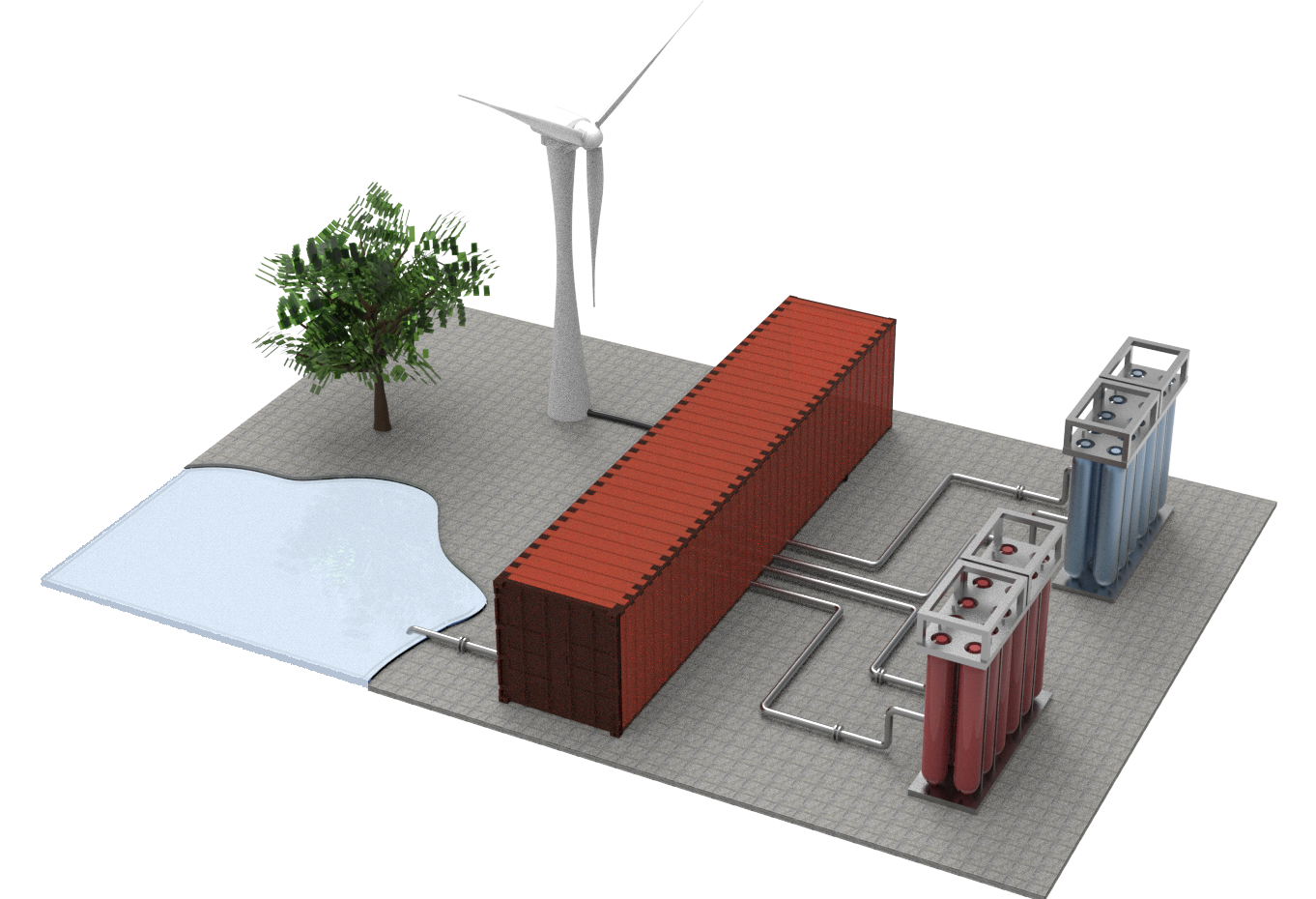

- On the other hand, the most know clean alternative to SMR today is water electrolysis. This process uses water and electricity as feedstocks and produces hydrogen and oxygen. While the produced H2 is clean, electrolysis is an expensive process. The cost of each kg of H2 produced using this process can be as much as 6 times more expensive than SMR.

- HyPlasma is a methane pyrolysis process that uses (renewable) electricity and (bio)methane as feedstocks. On the contrary of SMR, HyPlasma does not produce any CO2 because it uses the clean heat generated by our plasma torches to crack the methane molecule (CH4) into hydrogen and solid carbon powder (a by-product that can be valorized on the market). HyPlasma uses also electricity, similarly to water electrolysis, but at the same scale of production, it uses 5 times less electricity than electrolysis, making the operational costs more than 50% cheaper than electrolysis, while competitive with the cheap operational costs of SMR.

HyPlasma process

This video shows the chemical reactions producing hydrogen and carbon powder with methane.

HyPlasma OPEX

This chart shows the operational expenditure of HyPlasma compared to SMR and electrolysis.

In conclusionCheck our productsDownload our whitepaper about HyPlasma

SMR is cheap but polluting. Electrolysis is clean but expensive.

HyPlasma is both cost-effective and clean.

HyPlasma is highly flexible and scalable.